The Cost Estimating Series: Capital Cost Estimate Classes

Whether building new process lines or renovating existing lines, capital and operating and maintenance (O&M) cost estimates are important for project planning and implementation. The following will provide an overview of the classes of capital cost estimates. Different levels of capital cost estimates provide key input for decisions over the life of surface finishing projects from initial concept development through project selection and budgeting and on through completion of engineering design, procurement, and implementation phases. Understanding cost estimating methods and expected ranges of accuracy over a typical project life cycle is important for project financial considerations and communications and for decision support.

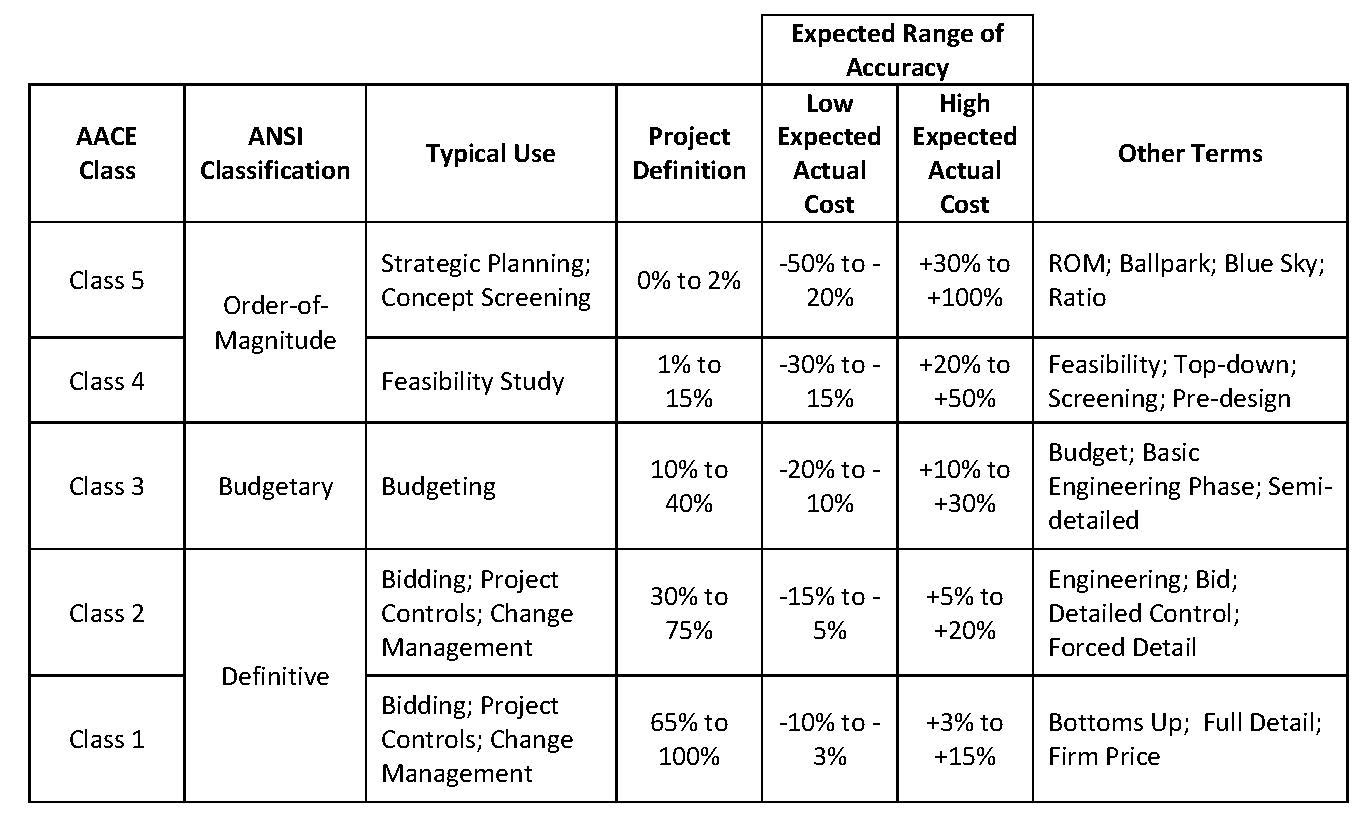

Table 1 is adapted from the AACE International practice guideline 18R-97 which applies the principals of cost estimating classification for process industry engineering, procurement, and construction projects (see reference below). This guideline is applicable for surface finishing process projects. Table 1 shows five AACE cost estimate classifications with the following information and characteristics:

Comparison of the five AACE classes to the three traditional, widely-used ANSI cost estimate classifications.

Typical uses of each class of estimate for support, from project conceptualization and development through project delivery and completion.

Level of project definition, expressed as a percentage of engineering and general project (e.g., scope, schedule, work breakdown structure, contracting strategy, escalation strategy) documentation development. For process projects, the engineering development typically progresses:

From early definition, including project location and constraints, general scope, processes and chemistries, production requirements and work envelopes, and process flow diagrams (PFDs).

Through process layouts and implementation phasing plans (if applicable), piping & instrument diagrams (P&IDs), utility flow diagrams, mass and energy balances, building integration plans, and equipment schedules.

Through detailed, multidiscipline engineering plans (structural, mechanical, electrical, I&C) and drawings (3D and 2D), specifications and data sheets, functional descriptions, O&M and commissioning plans, and lists of spare parts included in the project.

Expected Range of Accuracy: The accuracy ranges for each estimate class represent a range around an estimated expected cost value for a specific scope, including appropriate contingencies. The +/- percentage ranges represent an 80% confidence interval that completed actual project costs for a given scope will fall within the estimated ranges (assuming project implementation at specific location, under planned schedule, etc.). For each estimate class, the ranges for the low expected actual cost and high expected actual cost represent typical variances that result from individual project complexity and level of definition. These ranges also vary with estimating methods and engineering and estimating experience applicable for a specific surface finishing project. The ranges are asymmetric with higher percentage variations on the high costs. This is due to historical cost outcomes for specific project scopes that demonstrate factors combine to make the magnitude of probable final project cost increases from estimated values more likely than cost decreases.

Other Terms: These other commonly used estimate names are approximately correlated with the AACE estimate classes. Use of these other terms is not always specified with expected ranges of accuracy and may differ in meaning for different circumstances.

TABLE 1: Summary of AACE International Cost Classifications and Expected Ranges of Accuracy

NOTE: This table is based on AACE International Recommended Practice No. 18R-97: Cost Estimate Classification System – As Applied in Engineering, Procurement, and Construction for the Process Industries. TCM Framework: 7.3 – Cost Estimating and Budgeting (Rev. March 6, 2019).

In progressing from AACE Class 5 to Class 1 estimates, methodologies typically begin with more stochastic approaches (e.g., estimating from previous similar project costs using parametric calculations based on key quantities) and transition to more complete deterministic methodologies (e.g., semi-detailed to full line item detailed estimates). Appropriate contingencies are assumed to be included in each AACE class of estimate. Contingencies are separate from allowances. Contingencies account for non-specific/uncertain scope items and project risks. Contingencies are best estimated based on experience and review of similar past project estimated scope and costs compared to completed project actual costs with the same scope. When known scope items for a planned project are not included in stochastic extrapolations, or are not yet accounted for in line item cost details, specific allowances should be included in estimates for these known but mostly unquantified scope items (e.g., existing process demolition that was not part of a previous project used for a Class 5 estimate where the new project has process demolition; interconnecting process electrical or mechanical not yet detailed in a Class 4 or 3 estimate, etc.).